COB LED Displays: Reshaping Visual Technology with Integrated Precision

Sep 11,2025

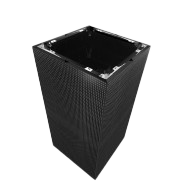

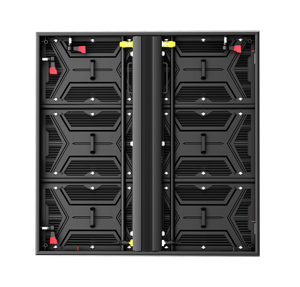

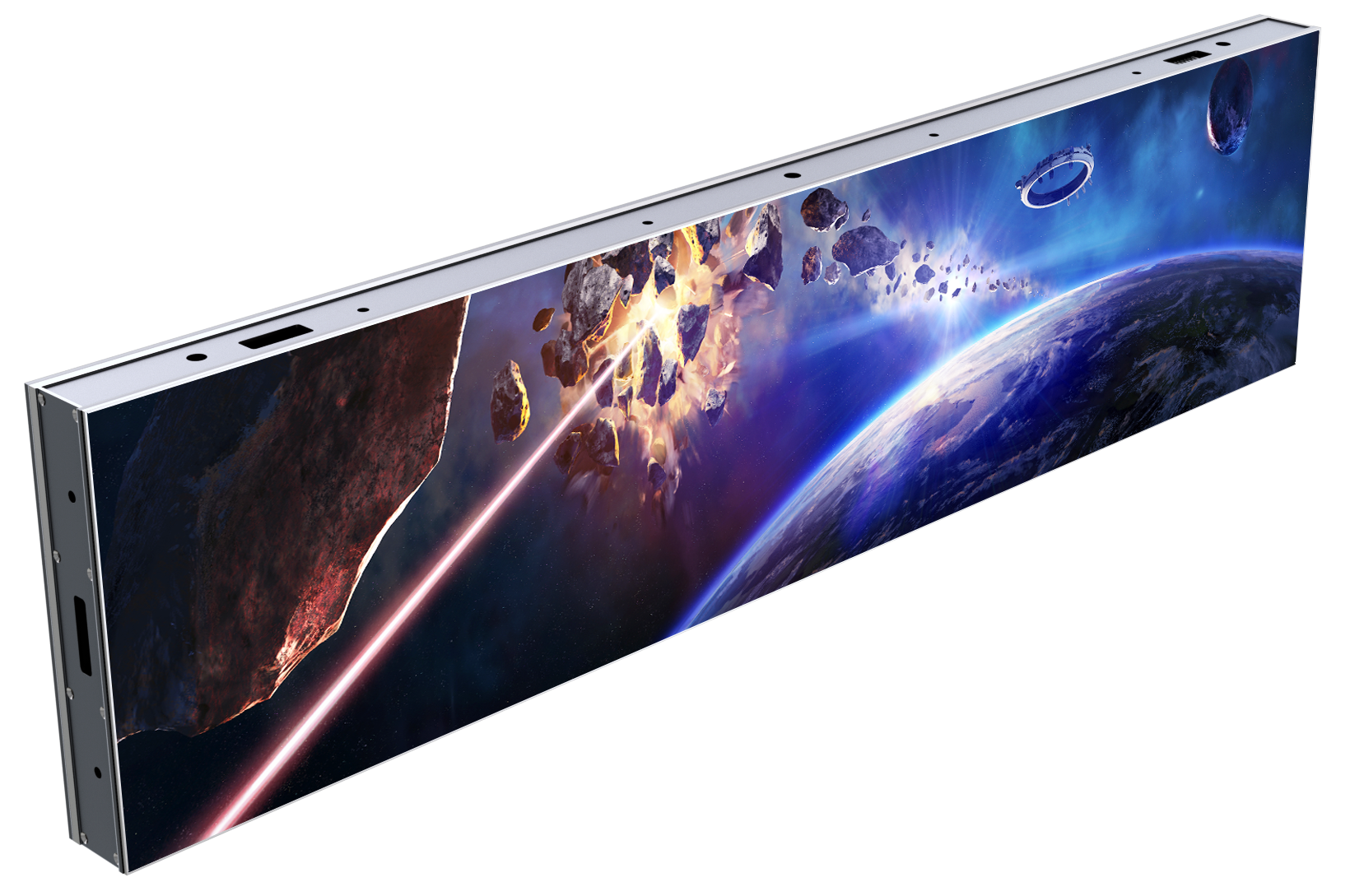

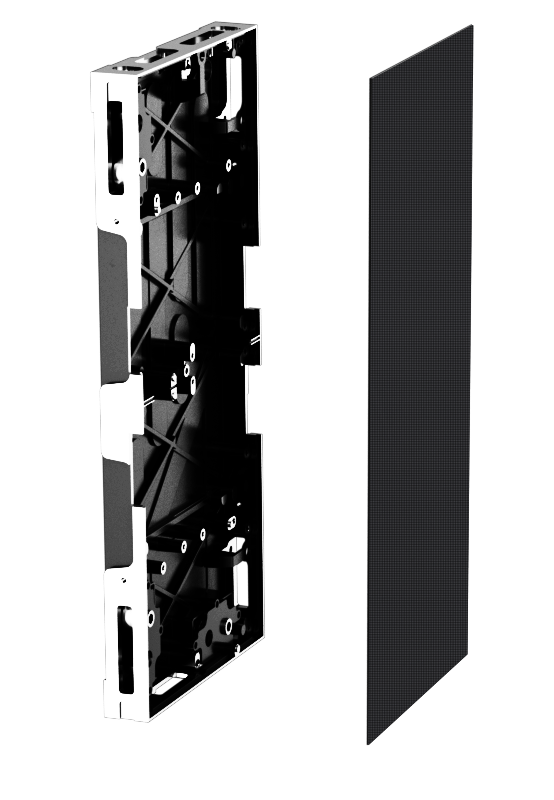

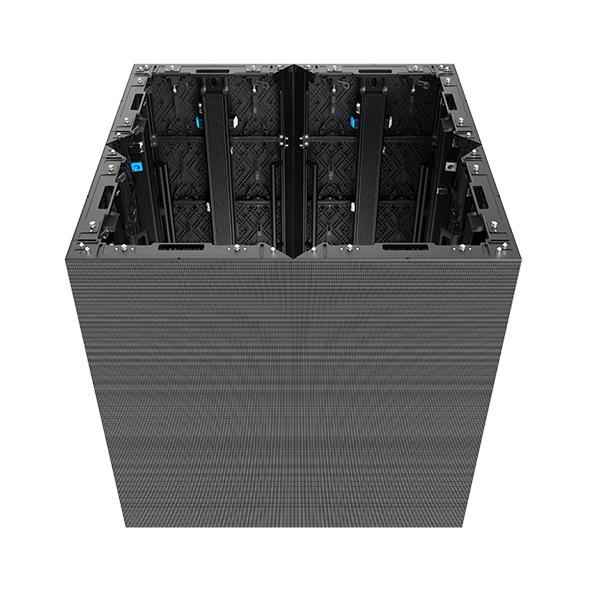

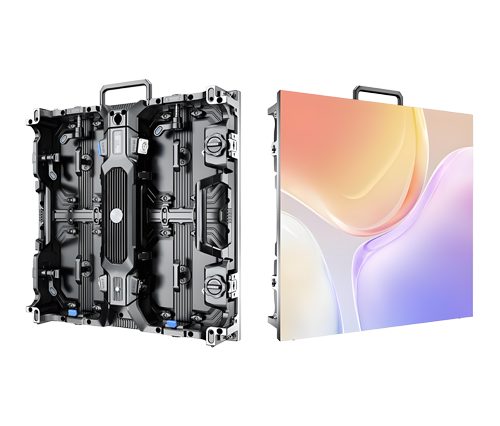

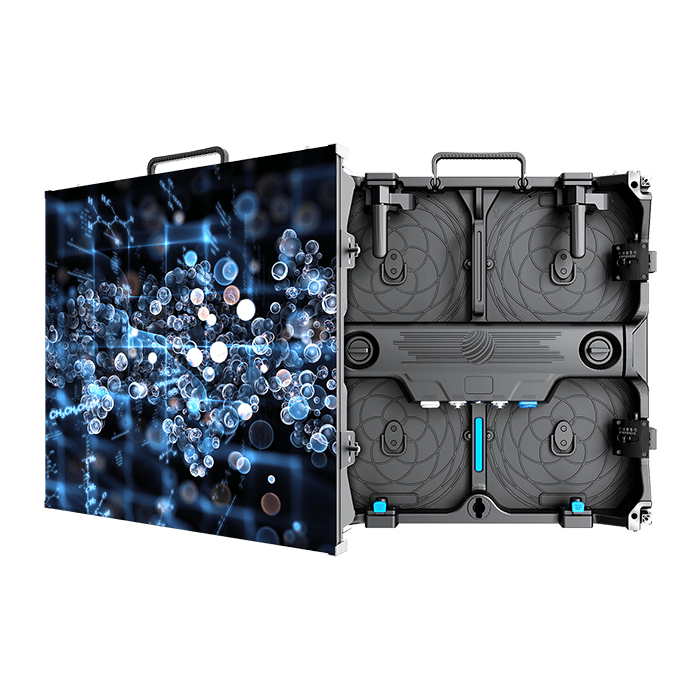

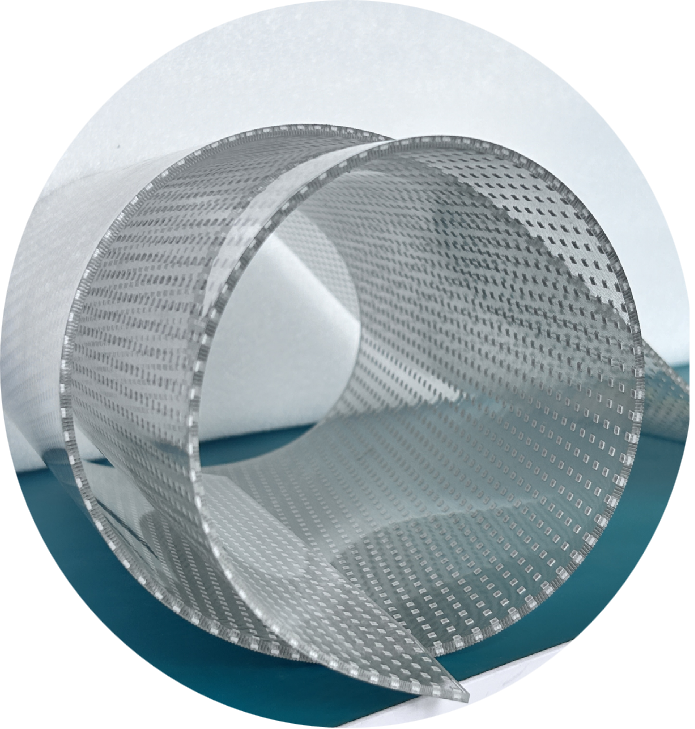

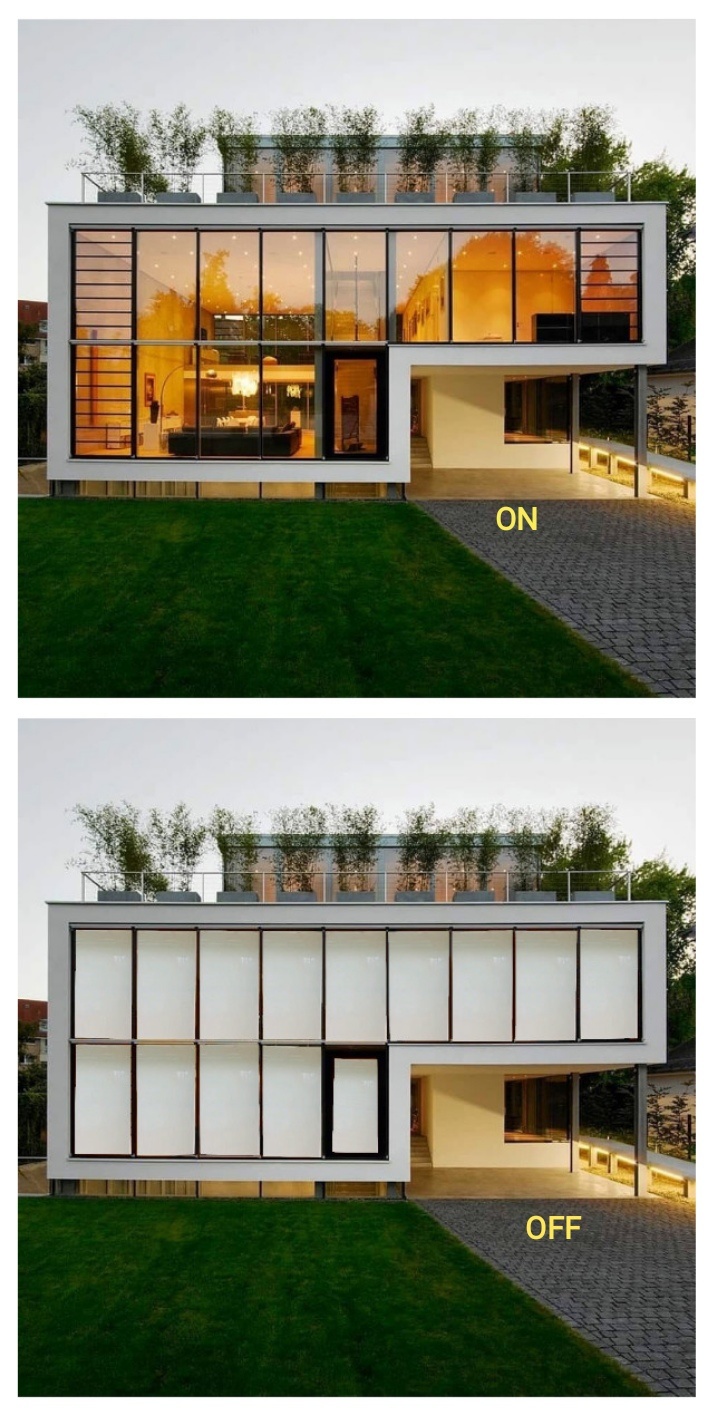

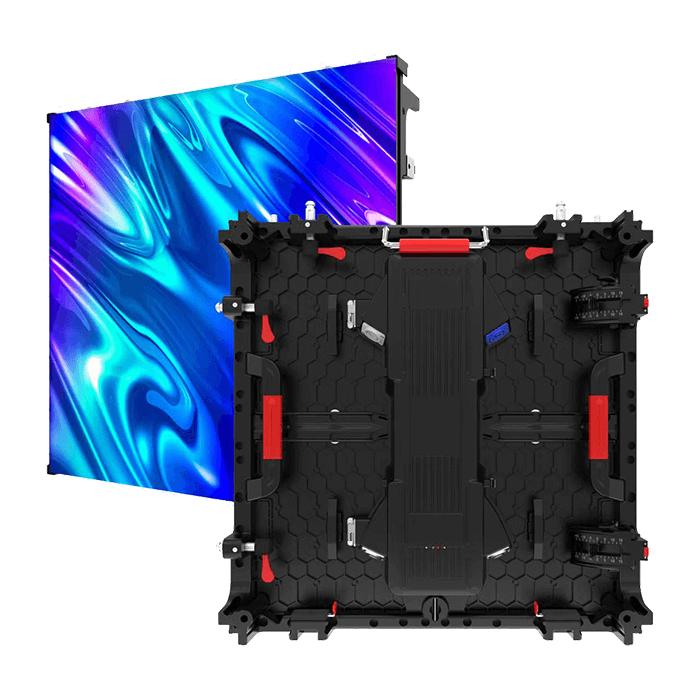

In the competitive landscape of visual technology, COB LED displays represent a significant engineering evolution, moving beyond conventional SMD (Surface-Mounted Device) solutions. Unlike traditional LED displays, where individual diodes are mounted separately, COB technology integrates multiple LED chips directly onto a substrate, resulting in a seamless, highly durable surface without discrete patches or gaps.

This structural innovation enhances the display’s physical robustness, making it resistant to impact, dust, and moisture. Such durability is particularly valuable in high-traffic environments like control rooms, public information displays, and transportation hubs, where reliability under demanding conditions is essential. The densely packed LED chips also contribute to higher pixel density, enabling finer image detail and wider viewing angles without color shift—a critical requirement in applications where viewing positions may vary.

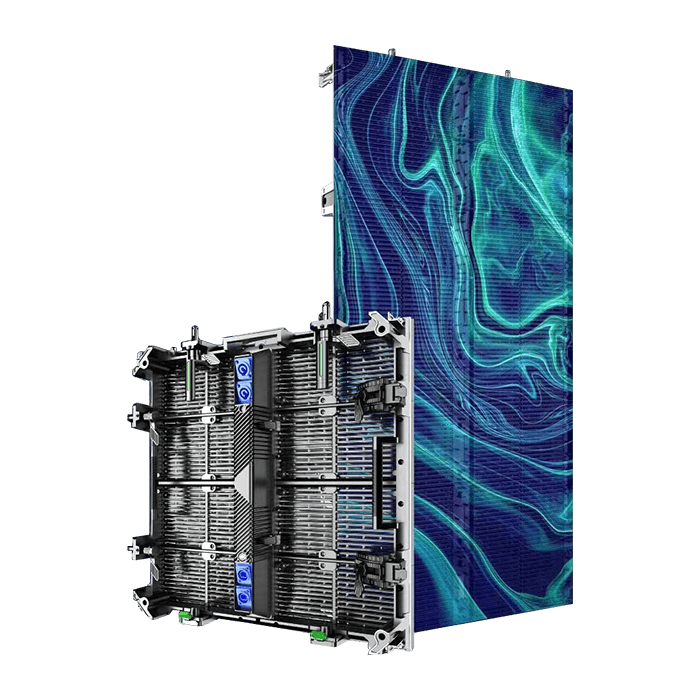

COB technology also addresses heat dissipation more effectively than SMD designs. By distributing thermal load across the substrate, COB modules operate at lower temperatures, which helps preserve color accuracy and extends operational lifespan. This makes COB-based displays suitable for extended-use scenarios such as broadcast studios, corporate command centers, and medical imaging facilities, where consistent performance over long periods is necessary.

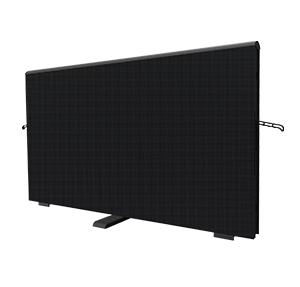

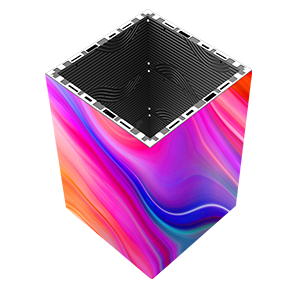

Applications of COB LED displays are expanding in sectors that demand precision and durability. In retail and museums, they provide crisp visual reproduction under bright lighting conditions. In industrial and healthcare settings, their ruggedness and stability meet stringent environmental requirements. Furthermore, their ability to maintain performance in variable temperatures supports usage in outdoor venues and digital signage installations.

While COB displays currently come at a higher initial cost compared to SMD alternatives, their long-term benefits in performance consistency and reduced maintenance are driving adoption among specialized users. As manufacturers like Geshino continue to refine production techniques, COB technology is poised to become a benchmark for high-end display solutions where reliability, clarity, and durability take precedence.

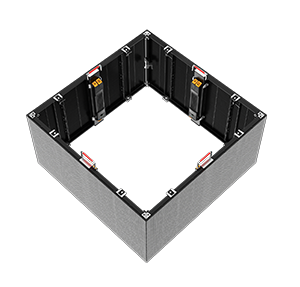

This shift underscores a broader industrial trend toward integrated modular design in electronics, highlighting how COB is not merely an incremental improvement but a foundational change in how LED displays are engineered and applied.

Hot Tags:

NEXT:

Contact Us

Related Posts

Illuminating Your Space: The Benefits of LED Advertising Signs

Transform Your Advertising Strategy with LED Billboards: A Comprehensive Guide